Founder & CEO of

KURVWEAR

Despite the high complication and fatality rates associated with permanent plastic surgery procedures, their popularity continues to rise.

It was this concern that led Alisha Athreya, the Founder of Kurvwear, to create a safe alternative to plastic surgery.

After her friend was hospitalized due to internal bleeding complications following a Brazilian Butt Lift; Alisha spent 9 months making 37 samples before created Kurvwear's Butt Bra™ was perfected.

Kurvwear is a rebellious, yet, progressive approach to traditional shapewear that empowers women by providing them with a garment that gives them the liberty to embody their individualised idea of beauty in a safe, non-invasive manner.

Our mission is at the core of everything we do - it drives us forward.

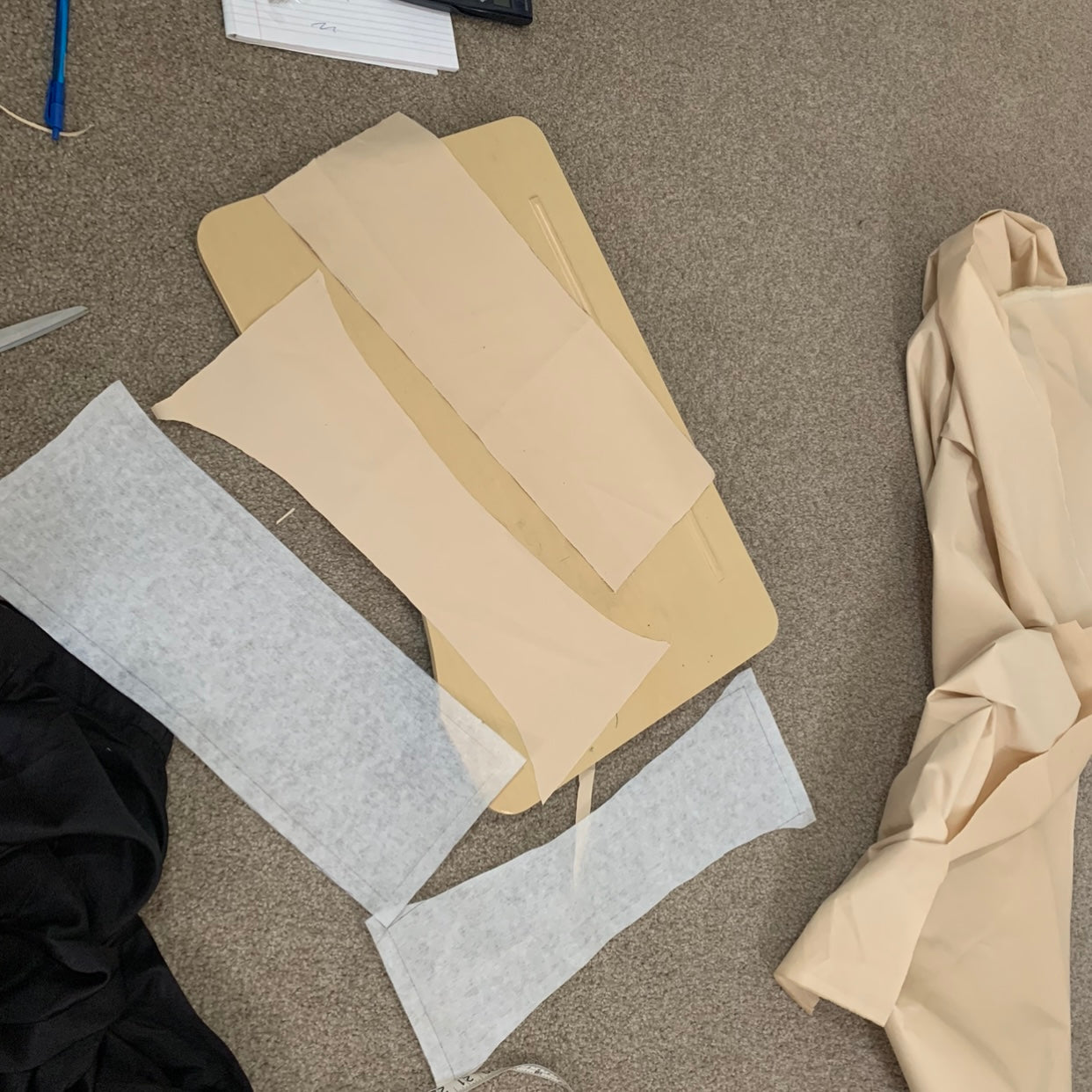

After learning the basics of sewing through YouTube, Alisha went to the fabric store & the local trade store. She bought 1.5m of muslin, 3m of fabric and 1m of construction foam for the padding prototypes.

She designed, developed and created The Butt Bra™ on her bedroom floor. This was the 10th sample made where Alisha combined panels of fabric together.

Using her mother's old sewing machine, Alisha made 32 samples before approaching manufacturers.

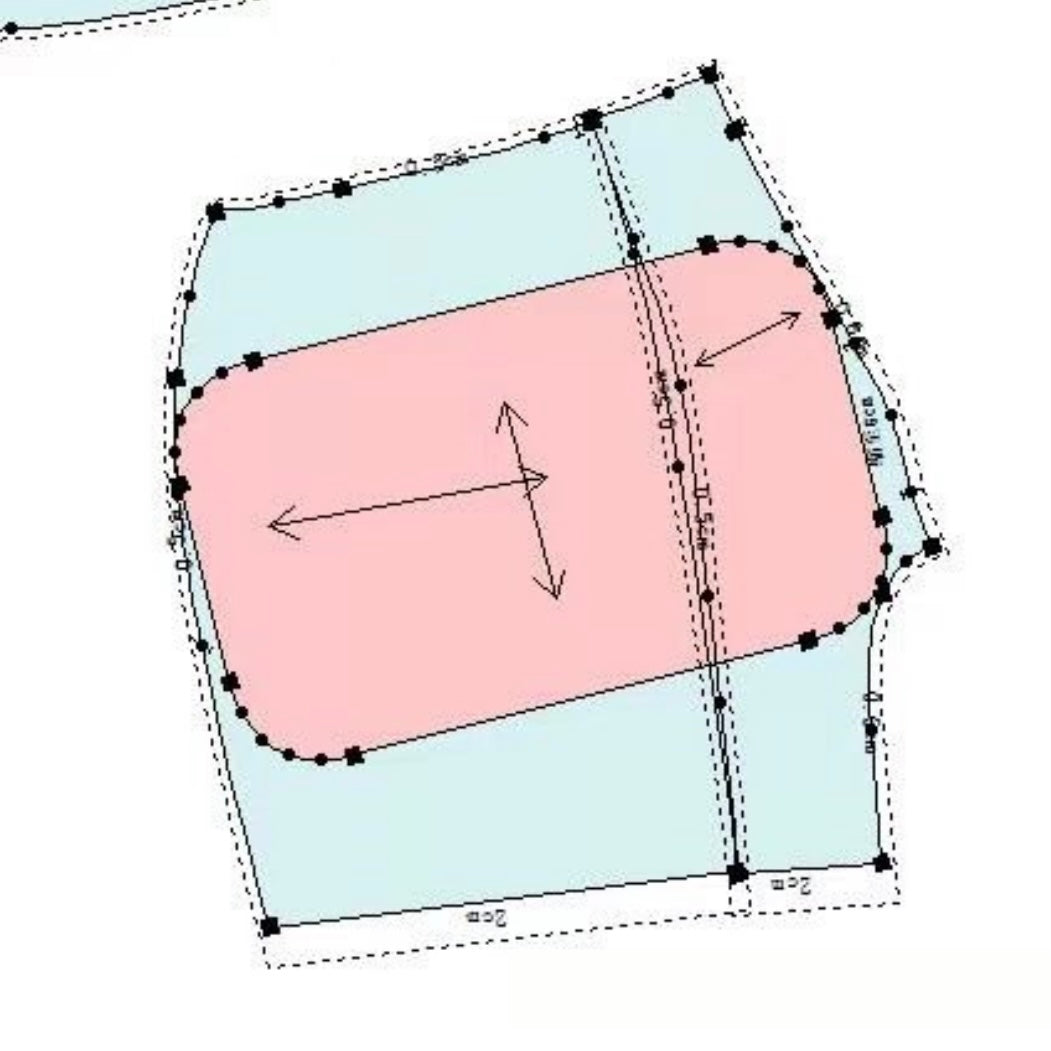

With the concept of The Butt Bra™ being new to the market, 50 manufactures had refused to work with Alisha. Luckily, the 51st manufacturer had agreed after which the initial renders of The Butt Bra™ were made. The Butt Bra™ went through 5 more stages of design & development before Alisha was happy with it.

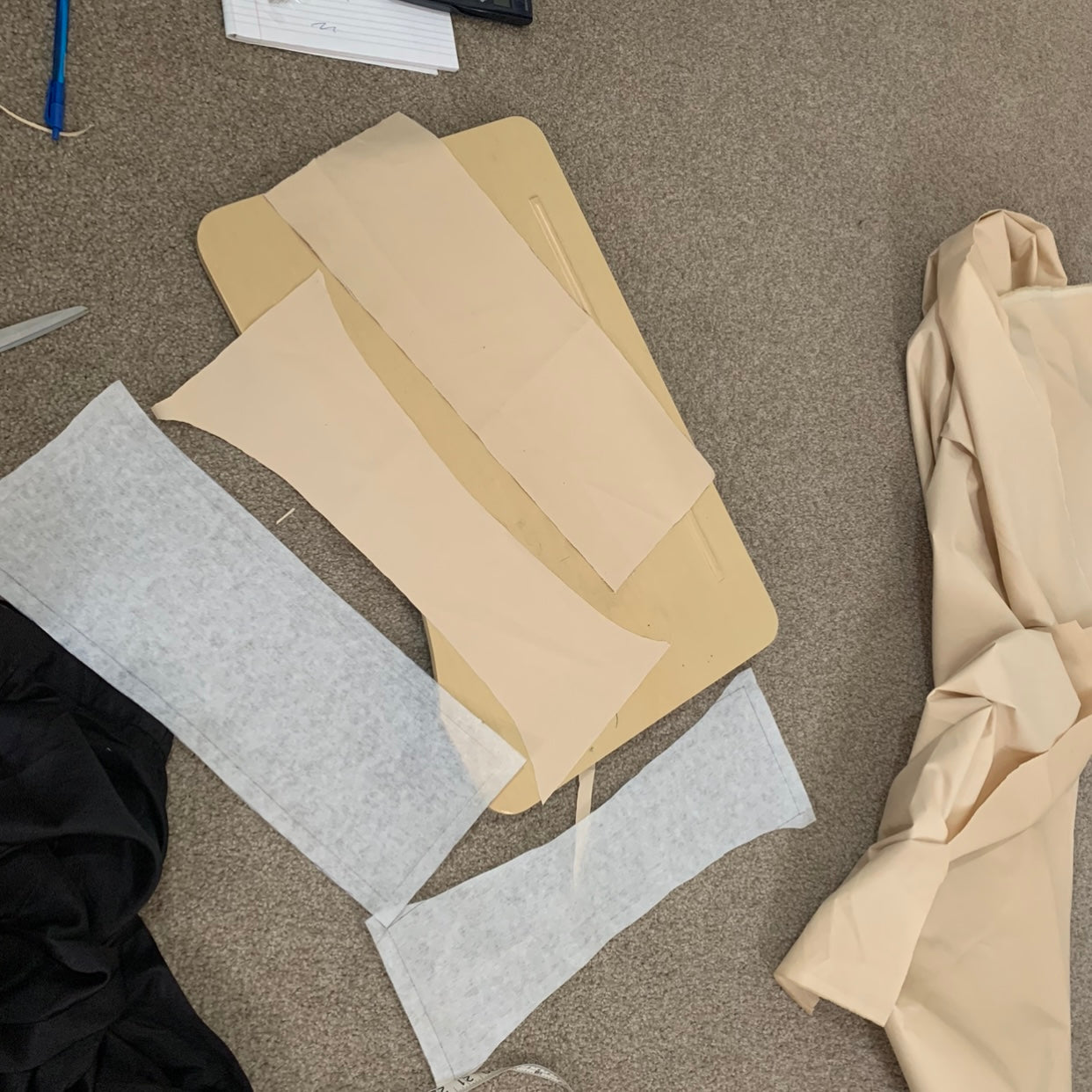

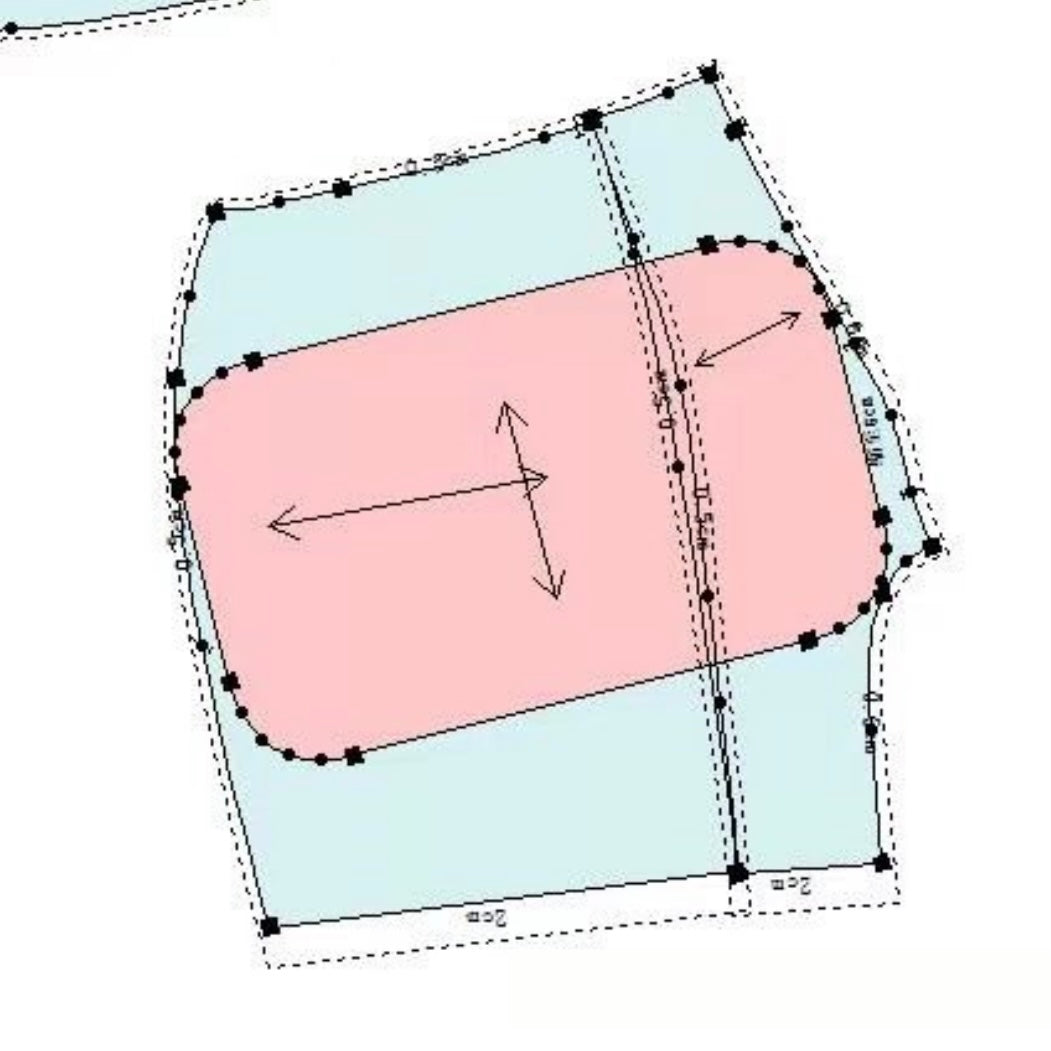

Alisha's priority was to ensure that the padding was inivisible to the eye. So perfecting the shape, size & volume of the padding was a challenge. After making 10's of padding prototypes using construction foam, this was the first finalised padding created.

Pictured is the first manufactured sample of The Butt Bra™. Following a lot of trial & error, testing, and 5 more stages of design & development - The Butt Bra™ was created. After 9 months & 37 samples, it's now yours.

After learning the basics of sewing through YouTube, Alisha went to the fabric store & the local trade store. She bought 1.5m of muslin, 3m of fabric and 1m of construction foam for the padding prototypes.

She designed, developed and created The Butt Bra™ on her bedroom floor. This was the 10th sample made where Alisha combined panels of fabric together.

Using her mother's old sewing machine, Alisha made 32 samples before approaching manufacturers.

With the concept of The Butt Bra™ being new to the market, 50 manufactures had refused to work with Alisha. Luckily, the 51st manufacturer had agreed after which the initial renders of The Butt Bra™ were made. The Butt Bra™ went through 5 more stages of design & development before Alisha was happy with it.

Alisha's priority was to ensure that the padding was inivisible to the eye. So perfecting the shape, size & volume of the padding was a challenge. After making 10's of padding prototypes using construction foam, this was the first finalised padding created.

Pictured is the first manufactured sample of The Butt Bra™. Following a lot of trial & error, testing, and 5 more stages of design & development - The Butt Bra™ was created. After 9 months & 37 samples, it's now yours.